Industry Knowledge Development

UPVC Shutter Window Factory

How to explain UPVC shutter windows?

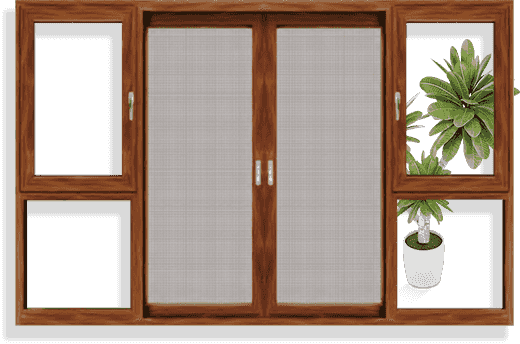

UPVC shutter windows are a type of window made from unplasticized polyvinyl chloride (UPVC) material. UPVC is a type of plastic that is strong, durable, and resistant to weathering and corrosion.

Shutter windows are windows that have movable shutters or louvers that can be opened or closed to control the amount of light and air that enters the room. These shutters are typically made of wood, but in the case of UPVC shutter windows, they are made from UPVC material.

UPVC shutter windows offer several benefits over traditional wooden shutter windows. They are more durable, require less maintenance, and are more resistant to weathering and corrosion. They also provide better insulation, which can help to reduce energy costs and improve the overall energy efficiency of a building.

Additionally, UPVC shutter windows are available in a range of colors and styles, making them a versatile option for both traditional and modern homes. They can also be custom made to fit specific window sizes and shapes, allowing for greater design flexibility.

What are the advantages of UPVC shutter windows?

Energy efficiency: UPVC windows are highly energy efficient and can help to reduce heating and cooling costs by minimizing heat loss or gain.

Low maintenance: Unlike traditional timber windows, UPVC windows require very little maintenance. They do not need to be painted, stained, or treated, and can be easily cleaned with soap and water.

Durability: UPVC is a strong and durable material that is resistant to weathering, corrosion, and rot. This makes it ideal for use in windows, which are exposed to the elements.

Security: UPVC shutter windows are designed to be strong and secure, with multi-point locking systems and reinforced frames to prevent break-ins.

Sound insulation: UPVC windows can help to reduce external noise levels, making them ideal for use in noisy areas or near busy roads.

Aesthetics: UPVC windows are available in a range of styles and finishes, so you can choose the perfect design to suit your home. They can be made to look like traditional timber windows, or can be finished in a range of modern colors.

Production process of UPVC shutter windows:

Extrusion: The first step in producing UPVC shutter windows is to extrude the UPVC profiles. The UPVC material is melted and then forced through a die to form the shape of the profile. The profiles are then cut to the desired length.

Cutting and Welding: Once the profiles have been extruded, they are cut to the required length and welded together to form the frame of the window. The welding process involves heating the ends of the profiles and fusing them together using a special welding machine.

Reinforcement: To ensure the window frame is strong and can support the weight of the glass, reinforcement is added to the frame. This is usually in the form of steel or aluminum bars that are inserted into the profiles.

Glazing: The next step is to glaze the window. This involves placing the glass into the frame and sealing it in place with silicone or a similar material.

Hardware installation: The hardware, such as the hinges, locks, and handles, is then installed onto the window frame.

Quality control: The final step is to perform quality control checks to ensure the window meets the required standards. This includes checking for any defects in the frame or glass and ensuring that the window opens and closes smoothly.

简体中文

简体中文 English

English