Industry Knowledge Development

Aluminum Awning Window Factory

What are aluminum awning windows?

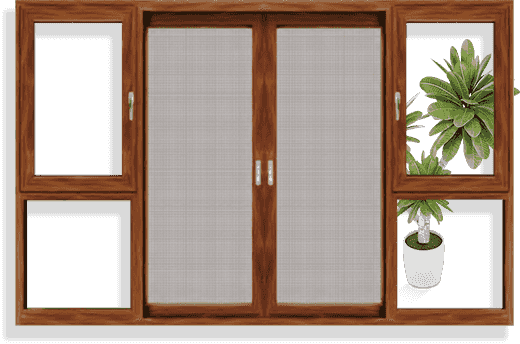

Aluminum awning windows are a type of window that is typically used in residential or commercial buildings. They are named after the way they open: the window sash is hinged at the top and swings outward from the bottom, creating an "awning" effect that provides ventilation while keeping rainwater out.

Aluminum is a common material for awning windows because it is lightweight, durable, and easy to maintain. The frames are typically made of extruded aluminum, which means that they are formed by forcing heated aluminum through a die to create the desired shape.

Aluminum awning windows are popular in modern and contemporary buildings because of their clean lines and minimalistic design. They are often used in combination with other types of windows, such as fixed windows or casement windows, to create a varied and visually interesting facade. Additionally, because they are hinged at the top, they can be left open even during rain showers, making them a popular choice for areas with frequent precipitation.

What are the characteristics of aluminum awning windows?

Aluminum awning windows are a type of window that is commonly used in residential and commercial buildings. They are known for their durability, strength, and low maintenance requirements. Here are some of the key characteristics of aluminum awning windows:

Material: Aluminum awning windows are made of aluminum frames and usually feature a single sheet of glass or multiple panes of glass. The frames are lightweight, durable, and resistant to corrosion.

Operation: Awning windows are hinged at the top and open outward from the bottom. They are typically operated using a hand crank or a lever, which makes them easy to open and close.

Energy efficiency: Aluminum awning windows are generally energy-efficient and can help to reduce heating and cooling costs. They often feature double or triple panes of glass, low-E coatings, and insulating gas fills.

Aesthetics: Aluminum awning windows can be designed to match the aesthetic of the building they are installed in. They are available in a variety of colors and finishes, and can be customized to fit the specific needs of the building.

Production process of aluminum awning window:

Extrusion: The first step in the production process is to extrude the aluminum frames. The extrusion process involves heating a billet of aluminum and forcing it through a die to create the desired shape of the frame. The extruded aluminum frames are then cut to the appropriate length.

Cutting and punching: The next step is to cut the frames to the precise length required for the window. The frames are also punched with holes to accommodate the hardware and locking mechanisms.

Assembly: The frames are then assembled using corner keys, which are inserted into the corners of the frame to provide structural support. The corner keys are then secured in place with screws or rivets.

Glass installation: The glass panes are installed into the frame using glazing beads or rubber gaskets. The glass is secured in place with a glazing spline or wedge.

Hardware installation: The final step is to install the hardware, such as the handles, locks, and hinges, onto the window frame. The hardware is usually made from stainless steel or other durable materials.

简体中文

简体中文 English

English