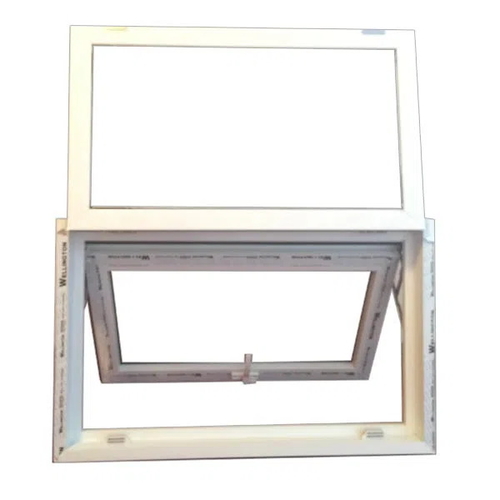

UPVC awning windows are a type of window that opens outwards from the bottom and is hinged at the top. These windows are made of unplasticized polyvinyl chloride (UPVC), which is a type of plastic material that is strong, durable, and resistant to weathering and fading.

The term "awning" refers to the fact that these windows are designed to provide protection from the elements. When open, the window creates an awning-like effect that allows air to flow into the room while keeping rain and other debris out.

UPVC awning windows are often used in bathrooms, kitchens, and other areas where ventilation is important but privacy is also a concern. They are also popular in modern architectural designs because of their clean lines and simple, unobtrusive design.

What are the advantages of UPVC awning windows?

Energy efficiency: UPVC windows have excellent insulating properties, which helps to keep the interior of your home comfortable in both summer and winter. They help to keep heat inside during the winter and outside during the summer, which can reduce your energy bills.

Durability: UPVC is a highly durable material that can withstand harsh weather conditions, including heavy rain, strong winds, and extreme temperatures. This means that UPVC awning windows are less likely to warp, crack, or fade over time.

Low maintenance: UPVC windows require minimal maintenance, as they are resistant to rot, rust, and corrosion. They can be easily cleaned with soap and water, and do not require painting or staining.

Security: UPVC awning windows are highly secure, as they are fitted with multi-point locking systems that prevent break-ins. They also have strong frames and toughened glass, which provide additional protection against intruders.

Noise reduction: UPVC awning windows are effective at reducing noise pollution from outside, making your home a quieter and more peaceful place to live.

Aesthetics: UPVC windows come in a wide range of colours and finishes, allowing you to choose a style that complements the design of your home. They also have a sleek and modern appearance, which can enhance the overall look of your property.

Production process of UPVC awning windows:

Design and Measurement: The first step is to design the window according to the customer's specifications and take accurate measurements of the opening where the window will be installed.

Profile Extrusion: The next step is to extrude the UPVC profiles for the frame and sash of the window. This is done by heating the UPVC material and forcing it through a die to create the desired shape and size.

Cutting and Welding: Once the profiles are extruded, they are cut to the required length and welded together using a specialized machine that melts the UPVC material to form a strong bond.

Glass Cutting and Installation: The glass for the window is cut to size and installed into the frame. This is done using rubber gaskets and sealant to ensure a tight fit.

Hardware Installation: The hardware for the window, such as the hinges, handles, and locking mechanisms, is then installed. This is done according to the manufacturer's specifications to ensure proper operation of the window.

Quality Control: Before the window is packaged and shipped, it undergoes a rigorous quality control process to ensure that it meets the manufacturer's standards for safety, durability, and performance.

Packaging and Shipping: Finally, the window is packaged and shipped to the customer or distributor for installation.

简体中文

简体中文 English

English